MAKKALIP is a plastic injection molder and tool manufacturer located at the Anatolian side of Istanbul, Turkey. We manufacture high precision injection-molded components used in a wide array of applications in diverse industries, including automotive, mechatronics, electronics, oil&gas, window&door, medical, consumer appliance and more.

We offer our customers complete manufacturing solutions including plastic raw material selection, part design and moldability optimizations, productive mold design and manufacturing, injection molding, insert molding, over-molding, value-added post-processes such as ultrasonic welding, tampon printing, laser marking, product assembly, functional testing, inventory management and finally distribution from door to door.

Committed to quality in every aspect of our business, we are a registered recipient of ISO 9001:2018 from Breau Veritas. Currently “SAP Business One” ERP system is being utilized and will be officially in use by 2020. Following this, IATF 16949:2016 will be acquired as all the infrastructure and process is ready for this step. MAKKALIP strictly follows process requirements of automotive projects and therefore applies 5 core tools of IATF 16949 as APQP, FMEA, MSA, SPC, and PPAP. Recently invested MITUTOYO MeasureLink software especially dedicated following SPC’s. Our Quality Lab includes many accurate measuring devices such as DEA CMM, MITUTOYO Countour Tracer, MITUTOYO Surface Roughness Device, Minitest Magnetic Wall Thickness Measurement, microscope, and others.

MAKKALIP is currently operating at the Anatolian side of Istanbul, which is very close to SABIHA GOKCEN International Airport, in its 2.500 m2 closed production facility. Engineering, Tool Design & Manufacturing, Injection Molding, Assembly&Control, Quality Lab, Warehouse, Logistics, and support functions located side by side at this same location.

Our injection molding facility includes 12 hydraulic machines, 8 ARBURG and 4 Krauss Maffei, ranging from 80 tons to 300 tons. In early 2019, we invested in MOTAN central drying and feeding lines.

All our injection molding machines have dedicated properties especially for engineering polymers such as bimetallic and coated screws for abrasive materials, smaller injection units with higher injection pressures, hot runner temperature controls embedded on the machine itself, automatic sorter systems in order to separate good and bad shots, fully equipped software for real-time production quality control. MAKKALIP also has expertize for multi-cavity hot runner tools (64, 48,32,24 cavity tools) utilized with outstanding hot runner systems and hot halves.

The complete machine setup is dedicated to high precision and on-time quality control.

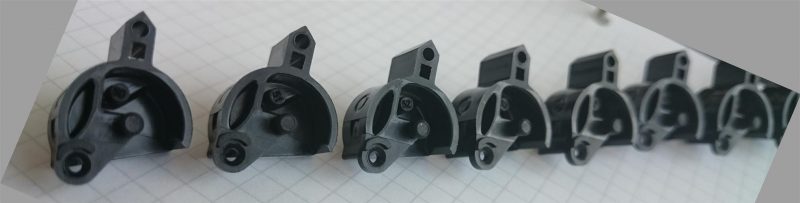

The secret behind high precision and long-lasting successful serial plastic part production is the MAKKALIP tooling facility. We manufacture our own plastic injection tools inhouse and also provide in-house maintenance to them. With this regard, we provide a complete lifetime guarantee for the tools that are manufactured in house. This means, our customer will have only one tool as long as the tool capacity covers the annual quantity. Complete maintenance costs, renewal costs will belong to MAKKALIP all along the project lifetime.